Sponsored By

ROCK

HARDWARE

Chockstone Photography

Australian Landscape Prints |

Chockstone Forum - Gear Lust / Lost & Found

Chockstone Forum - Gear Lust / Lost & Found

Rave About Your Rack Please do not post retail SPAM.

| Author |

|

|||||

10:31:04 PM |

Yes,another pesky question... I was hunting through the Black Diamond website. In their website, they mentioned that their carabiners are made from 7075 Aluminium. Does anyone know if this would be the same material used in making their camalots? Cheerio Ah, no need for any responses, I've found my answer. |

|||||

8:55:43 PM |

On 10/04/2005 ti wrote: >Hello, another night in front of the computer, but this time I'm missing out on watching Zoolander! >I hadn't realised that others might be interested in my findings, rather, I presumed people knew the answers but just couldn't be bother responding to another tedious question. >Anyway, whilst reading Climbing Anchors by John long (page 41) I found out that the handle of the BD cam is made from stainless steel, the trigger is made from Nylatron and the cam lobes are made from 7075-T6 Aluminium. The cam lobes are stamped out of the aluminium. This surprised me, as I thought it would have undergone a forging or casting process. >The book was written in 1993, so the new cams may be made from a different material. >Anyway, I've written this post twice (because the computers playing up) so I'm going to keep it short. >Cheerio, >ti >PS. If anyone is interested in the physical properties of these materials, then you can look them up on a website called matweb I believe that the new cams are laser cut. This is why they are now cheaper, and has allowed a different shape that helps make them lighter. Would have cost a fortune to set up. But they had to do something now that the patents are running out. |

|||||

10:03:27 PM |

On 10/04/2005 ti wrote: >Yeah, I feel that the reduced weight is due to the removal of excess/ redundant material rather than the introduction of a new super alloy. But if someone has read any new material about these new BD cams and can site the reference, I'd appreciate that. >also, whilst reading a paper titled 'An Elastic Model of the Holding Power of Spring Loaded Camming Devices Used as Rock Climbing Anchors' by Dave Custer, he wrote of testing two popular brands of SLCD's one contained the metal 7075 aluminium whilst another contained 6061 aluminium. However the brands were not named. >The paper is quite an interesting read, as is 'A Brief Discussion of the Engineering Principles Used in the Design of Camming Devices for Rock Climbing' and another paper I'd suggest is 'Carabiner Testing' by Jon Graham I'm pretty sure that all cams are either 6061 or 7075, the latter being the harder wearing. That article is a good one, and a very good starting point to learn about cams. I think that most of the weight reduction in C4's would have been from the switch to c type cable handle. Also would explain the lower strengths. |

|||||

11:21:27 AM |

On 12/04/2005 ti wrote: >This is secondary information, but I had heard that when the BD rep. came through Melbourne last year and spoke of the new Cams. >Some of the weight reduction was also from making the axle hollow. >BD had tested a batch of their cams to the point of failure and noted where they didn't fail (which was the axle). >From there they decided that the axle was over-engineered. They converted the solid axle to a hollowed section. >Also, the larger cut-aways would also contribute to the weight reduction. >Anyway, it's a nice cam... Hmm, usually when manufacturers use hollow axels they switch to a larger diameter. I just checked my camalots and have no idea if they are hollow or not. They do seem quite a small diameter though. It would be interesting to see a breakdown of where the weight savings were made. I was wondering if there has been a composition change as the axels on mine do not look like plain old steel. |

|||||

12:52:31 AM |

On 18/04/2005 ti wrote: >Yeap, you're right. The hollow axle is only on the new large cams. Have you got the new cams? I have from the smallest double axel (which is the old type stem) up to a no4 in camalots. I also have a full set of aliens to complement. Above that I have a no6 friend, still got a gap to fill between them, and will probably get another no2 and 3 c4 as well. |

|||||

1:38:25 AM |

The cost saving in using laser cutting over stamping, is that with laser cutting you put a but of code into a computer and it will get the laser cutter to cut it to that precise shape. With stamping, you need to get dies made to cut the aluminium to the correct shape, small changes to the design means extensive modification to the die or even a new die, both of which are very expensive. I hope they are heat treating / ageing the aluminium after laser cutting, as if it's pre-treated all the mechanical properties gained will be lost because of the conduction of heat during the laser cutting. In reality, water jet cutting would probably be a cheaper option as you could purchase the aluminium sheet already heat treated / aged. Matweb is a useful tool, even if the materials designations are very US orientated. |

|||||

11:07:40 AM |

On 20/04/2005 rightarmbad wrote: Above >that I have a no6 friend .. Bloody hell! Must be a big bugger. How often do you carry it? |

|||||

1:00:49 PM |

On 10/04/2005 ti wrote: >Anyway, whilst reading Climbing Anchors by John long (page 41) I found >out that the handle of the BD cam is made from stainless steel, the trigger >is made from Nylatron and the cam lobes are made from 7075-T6 Aluminium. >The cam lobes are stamped out of the aluminium. This surprised me, as I >thought it would have undergone a forging or casting process. > >The book was written in 1993, so the new cams may be made from a different >material. It'd be intersting to know if they've changed or not since the old design. 7075-T6 was all the rage in the aeroplane industry some time ago but is less popular today for corrosion reasons. I think castings are a bit nasty from a brittleness and wear point of view. Thanks for the references. |

|||||

11:32:54 PM |

A laser cutter doesn't go blunt like a normal cutting or stamping tool. Less maintainence. Computer controlled, less retooling, easier prototyping. Can cut shapes that are impossible with conventional tools. Heat is very localised and does not require/damage heat treating. All in all a far better way to go if you can afford the start up costs. Forging would be detrimental to the ability of the lobe to conform to the rock. After all thats why aluminium is used and not some harder metal. 7075-T6 was used in the air because of its strength to weight and resistance to fatige. 6000 and 7000 series is used in climbing at the whim of the designer to satisfy their desire for whatever amount of stick/wear they design into their cams. 6000 bites more but also wears more. The 7000 series used in the C4's would allow more skeleton type reliefing due to it's higher strength. Happy wondering about different alloys next time you choose which cam to grab off your rack. P.S. The T6 refers to a type of heat treating applied. I don't think that T6 is used in cams. I could be wrong though. | |||||

9:06:07 AM |

Original interviews with Ray Jardine in Mountain 66 or 67 mentioned T6 I recall. Anyone still have these editions? |

|||||

2:40:01 PM |

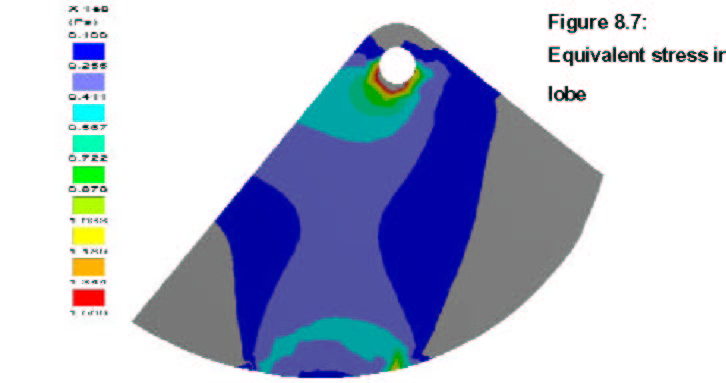

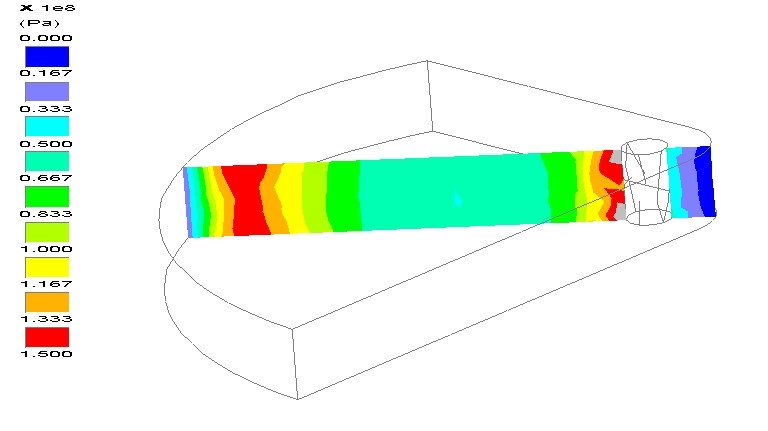

On 19/05/2005 ti wrote: >Hi! >Just wanting to thank everyone who's given me some suggestions, guidance, feedback or advice... thanks for the help. I'm now in the latter stages of this cam project and have come up with some feasible modifications to the existing camalots and how cams might be used, nothing revolutionary, just some ideas that may grow over time. But hopefully sufficient for the assesment of this project! >Cheers, ti my uni thesis was an FEA analysis of cams. I even made up some new lobe designs with a CNC mill and built them into cams. It was a lot of fun :) I made mine from a billet of T6 6061. |

|||||

11:06:08 PM |

On 19/05/2005 ti wrote: >Neil! Where were you when I first posted this? >Oh well, maybe when I'm doing my final year project, I could ask you afew questions? >PS. I wouldn't mind reading your thesis, if that alright? What was the final shape that you decided on? What degree were you doing? Yes please share your newfound knowledge with us all. |

|||||

3:28:20 AM |

When I First wanted to know How and Where cams came from, my mother sat me down and told me, "When a Mummy Cam and a Daddy Cam love each other very much..." I dont remember the deatils after that, but it has something to do with "Jugs", "Nuts" and a "Woodie" |

|||||

12:21:06 PM |

degree = mech eng. some typical FEA screen shots are shown below. did lot's of sticky beaking into all sorts of design aspects. it was a really fun thesis.   Research can be tough !!!! |

|||||

8:41:52 PM |

This is a link to a paper that I found interesting. I'm not sure anyone could be better qualified to write such a paper. Vaino Kodas is a mechanical engineer with Professional Engineer (P.E) certification. He also leads at 5.13 and has established hundreds of new routes. http://www.vainokodas.com/climbing/cams.html |

|||||

9:52:02 PM |

Good link. | |||||

7:44:05 AM |

Send the guy an email. Hes a climber and as far as I know, doesn't have a vested interest in the gear he tests. Mabe he'll help you out. When you are done though, you gotta promise to share. : ) |

|||||

10:42:38 PM |

I have some stuff saved from my old computer. I will dig it up. There was pull to destruction tests of all the major brands and a breakdown of the failure mechanism for each cam. Somewhere I had a FEA of cam lobe deformation and expected failure points. See what I can still find. I found that the information of frictional losses through the cam under load to quite illuminating. Probably the reason that aliens have such a good reputation is the low losses due to shorter stiffer shafts. |

|||||

1:40:09 PM |

Seems to be quite a community of amatuer cam designers out there. For anyone thats interested, there is an MSC package out there called robust design. Its an FEA module that allows you to varify that your design/model does not fall over with small variations in fundamental parameters. So for example, if you wanted to check that variations in manufacturing tolerances, pin stiffness, friction variation, assymetric or flared placements did not result in a massive drop in overall strength then you can put them in as variables and it will do a range of problems to get a good statistical handle on it all. As there are many stories of cams pulling out, this kind of analysis would be pretty interesting to see. |

|||||

10:30:24 PM |

"For anyone thats interested, there is an MSC package out there called robust design. Its an FEA module that allows you to varify that your design/model does not fall over with small variations in fundamental parameters." Now thats something that I haven't done. I thought that it would be quite tedious to implement. Info, I doubt that I could dig it up in time. It's something that I been trying to get around to for ages. Unfortunately the drive was ravaged by a virus. I have been meaning to set up a sacraficial computer so as not to risk any valuable information. I am sure that the files are recoverable, it's just that life keeps getting in the way. The pull to destruction tests were gleaned from the internet and I am sure that they are still out there somewhere, it's just that I cannot remember where the site was. Sorry. |

| There are 20 messages in this topic. |

Home | Guide | Gallery | Tech Tips | Articles | Reviews | Dictionary | Forum | Links | About | Search

Chockstone Photography | Landscape Photography Australia | Australian Landscape Photography | Landscape Photos Australia

Please read the full disclaimer before using any information contained on these pages.

Australian Panoramic |

Australian Coast |

Australian Mountains |

Australian Countryside |

Australian Waterfalls |

Australian Lakes |

Australian Cities |

Australian Macro |

Australian Wildlife

Landscape Photo |

Landscape Photography |

Landscape Photography Australia |

Fine Art Photography |

Wilderness Photography |

Nature Photo |

Australian Landscape Photo |

Stock Photography Australia |

Landscape Photos |

Panoramic Photos |

Panoramic Photography Australia |

Australian Landscape Photography |

High Country Mountain Huts |

Mothers Day Gifts |

Gifts for Mothers Day |

Mothers Day Gift Ideas |

Ideas for Mothers Day |

Wedding Gift Ideas |

Christmas Gift Ideas |

Fathers Day Gifts |

Gifts for Fathers Day |

Fathers Day Gift Ideas |

Ideas for Fathers Day |

Landscape Prints |

Landscape Poster |

Limited Edition Prints |

Panoramic Photo |

Buy Posters |

Poster Prints